3D Laser scanning services & As-Buit Surveys

We rebuild the geometry of elements and infrastructures using 3D laser scanner technology

Digitalization of industrial facilities

We are 3D laser scanning and modeling consultants who help industrial engineering design professionals minimize risk, save time, and execute projects. Industrial projects are often affected by uncertainty. We provide 3D laser scanning services designed to eliminate these drawbacks. Industrial and manufacturing facilities are very dynamic spaces, so your 3D laser scanning solutions must also be dynamic.

In manufacturing and industrial facilities, materials and products must flow through factories with great efficiency to keep costs and productivity low. That is one of the reasons why factories are constantly optimizing plant designs: moving elements, removing old equipment, adding new equipment, etc. For example, automotive plants make changes every year to meet the manufacturing requirements of the new car models. Over time, all these changes can lead to a poor understanding of what is actually in the factory, where these assets are located and how much space they consume in three dimensions.

Our job is to use our laser scanning solutions to create a 3D reality capture of the installation and its contents. Once the point cloud model is transferred to our customer, they can be integrated into a modeling solution (eg Autodesk Factory Design Suite) and used as a basis to help locate equipment and create new streams of more efficient products.

3D laser scanning in industrial engineering design:

-

Product design: 3D laser scanning can be used to create accurate and detailed models of products and parts. This information can then be used to design new products and parts, or to optimize existing designs.

-

Facility design: 3D laser scanning can be used to create accurate and detailed models of industrial and manufacturing facilities. This information can then be used to design new facilities, or to optimize existing facilities.

-

Renovation and modification planning: 3D laser scanning can be used to create a record of the existing conditions of a facility. This information can then be used to plan renovations or modifications to the facility.

-

Quality control: 3D laser scanning can be used to compare physical products and parts to their digital models. This information can then be used to identify and correct any quality problems.

Benefits for Industrial Sites:

-

Minimize shut down times: Most scans can be performed while the industrial facility is still in operation.

-

Simplify Complex Environments: Measure even the most complicated industrial facility quickly and accurately.

-

Eliminate change orders and ensure accuracy of prefabricated materials: Industrial laser scanning and as-built modeling for BIM and Revit is much more accurate than traditional methods.

-

Safely measure areas difficult or impossible to measure by hand: Laser scanning allows you to get measurements in hard to reach areas without putting someone in unsafe conditions.

We can also perform more specific tasks, such as scanning the desired route of the incoming equipment to its final position. By creating a real capture, we can help our clients accurately calculate the constraints and 3D space spaces. You can model the dimensions of the new equipment and move it virtually through the path in the point cloud model to find conflicts and interference, minimizing costs and greatly reducing downtime on the line.

Industrial maintenance and facilities management require visibility. Older facilities, in particular, require centralizing information. Documentation about machines, pipes, electrical equipment and previous renovations is often stored in scattered paper sources. Sometimes, this information is stored only in the memories of some experienced employees. This may present a nightmare scenario for planning and maintenance, particularly for the new administration.

Point clouds, 3D models and laser scans are a simple way to capture, store and visualize detailed information about physical space. Now they are being used proactively in high-end construction, renovation and manufacturing projects. Recently, this technology has been used with great effect for the management of facilities and the continuous maintenance of existing spaces.

Advantages of using laser scanning in industrial facilities:

Speed and Efficiency: Our 3D laser scanning service delivers incredible detail in a short amount of time. Survey work that would have taken days or weeks to complete can now be completed in hours. For as-built, topographic, detail, and engineering surveys, time to completion has never been faster. Laser scanning also enables data collection in a variety of circumstances, including low-light scenarios.

Accuracy and detail: Laser scanners (using LiDAR) acquire a great deal of information about the scanned location in a matter of seconds. The laser sweeps across an area or object and returns millions of data points. More detailed and accurate information leads to more complete As-built design projects, resulting in better retrofit designs. This leads to less time-consuming construction re-work and the ability to manufacture in the factory rather than in the field. This translates into less facility downtime.

Security. From a safety perspective, laser scanning allows us to inspect areas that might be considered unsafe without endangering ourselves or team members. For example, measuring the cliff face would have put the surveyor in a position of health risk, but with scanning, our surveyor places the instrument at the base of the cliff and lets the machine do all the measurements.

Laser scanning and industrial modeling:

The quality of the finish on an industrial project or product is directly determined by the quality of the planning and data collected to support decision making, design requirements, and manufacturing processes.

3D laser scanning technology ensures that the quality and precision of the measurements taken for parts, equipment and spaces are of the highest caliber to guarantee the quality of manufacturing and execution of the project.

Our 3D laser scans take a permanent record of objects and spaces with ultra-high accuracy and precision. With this, architects and engineers recreate digital models of the project or use the scans directly in model overlays, comparisons or presentations.

High-definition 3D laser scanning technology scans any object or space to create meshed surface models or point cloud models for export and use in BIM or 3D modeling software systems (Autodesk Revit, Navisworks, Solidworks, Autocad, Graphisoft Archicad, etc.) for the creation and review of 3D Models.

Utilizing 3D laser scanning technology allows our expert engineering team to quickly and accurately reverse engineer parts or components that are discontinued or have too long a lead time to replace or stock parts that are critical to your equipment. processing. It can also be used to effectively repair parts and components that are worn or difficult to measure by hand with typical measuring equipment (tape measures, calipers, etc.).

Scanphase collaborates with architecture and engineering studios in Europe (Portugal, France, Italy, Spain, Malta, Netherlands, Germany, Belgium, Turkey and others) based on our experience we offer our laser scanning services and generation of rich models using the tools most used design tools on the market (Graphisoft Archicad, Autodesk Revit, Navisworks, Autocad, ...).

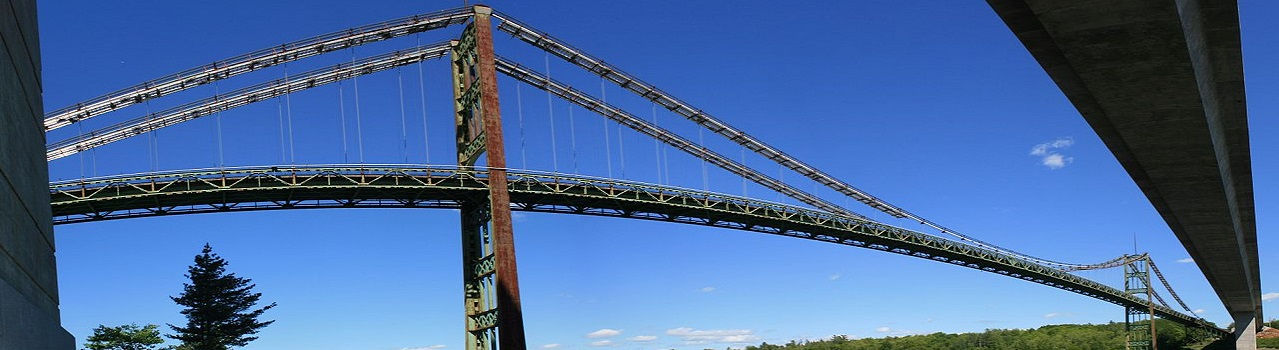

Industrial facilities laser scanning Image gallery